One of your main considerations regarding the configuration of your office or commercial premises is how you connect and power electrical equipment. Where you place plug sockets and other data ports in relation to employees’ desks and workspaces will determine your rooms’ eventual layout.

Many organisations get around this potential problem by installing underfloor power. Running all electrical and data wiring under the floor means you avoid trailing cables beneath desks and across floors and causing a trip hazard. It also enables you to install sockets where they are most accessible.

The two most common floor power solutions are floor boxes and busbars. Additionally, you can also find cable hives and floor grommets.

Although these are separate products, they are often used in combination to create one integrated power distribution system.

Floor boxes are boxes made of steel/stainless steel and plastic, designed to be installed into raised access floors. They come in a range of sizes and there are different boxes for different types of flooring.

Installation

To install a floor box, you create a suitably sized cavity in the floor then place the box inside it so the lid is flush with the floor surface. You then connect the box to the cables that run under your floor.

The box is sectioned into compartments, each of which houses an accessory plate and the necessary wiring. Which accessory plates you fit depends on the type of power or data connection you need (for example, mains power, Ethernet, HDMI etc.).

Many newer models of floor box are made to be “fast-fitting”—designed to be installed quickly and easily, without the need for any tools or specialist equipment.

Boxes designed for installation in a concrete or screed floor are made to specifications that ensure they will be waterproof and watertight.

Application

Most organisations can benefit from underfloor power. Indeed, floor boxes are used widely in a variety of environments such as offices, airports, hotels, schools, hospitals and public buildings such as council offices.

Busbars are metallic tracks which have a series of plug sockets built into them. These tracks feed the building’s mains power to wherever electricity is needed, such as floor boxes, electrical sockets or other outlets. One of their main purposes is to ground and conduct electricity, so power can be distributed safely throughout a building.

How it works

Busbars carry power from the transformer to the switches and fuses that control the electrical equipment. The tracks contain conductive strips (usually made of copper) housed within metallic trunking. A feed unit connects to the building’s mains supply, and there are tap-off units wherever the electricity needs to branch off to feed floor boxes or other outlets.

Installation

Most busbar systems are modular powertracks and tend to be installed under the floor, in the cavity of a raised access floor. As they are modular, they snap together to create one long length of track.

The usual recommendation is to lay them in parallel lines and space them no more than five metres apart and no more than 2.5 metres from the nearest wall.

Application

You can find powertrack-style busbars in offices, factories and workshops, supermarkets and shopping centres, hospitals, universities and schools.

Cable hives are an alternative to floor boxes and slab boxes for providing underfloor power and/or data sources beneath desks. Quick and easy to install, they go into a cavity in the floor and keep cabling systems tidy and out of sight.

Manufactured from strong polycarbonate, they have a foam inner lining which grips the cables securely, thus preventing them from being damaged or disturbed.

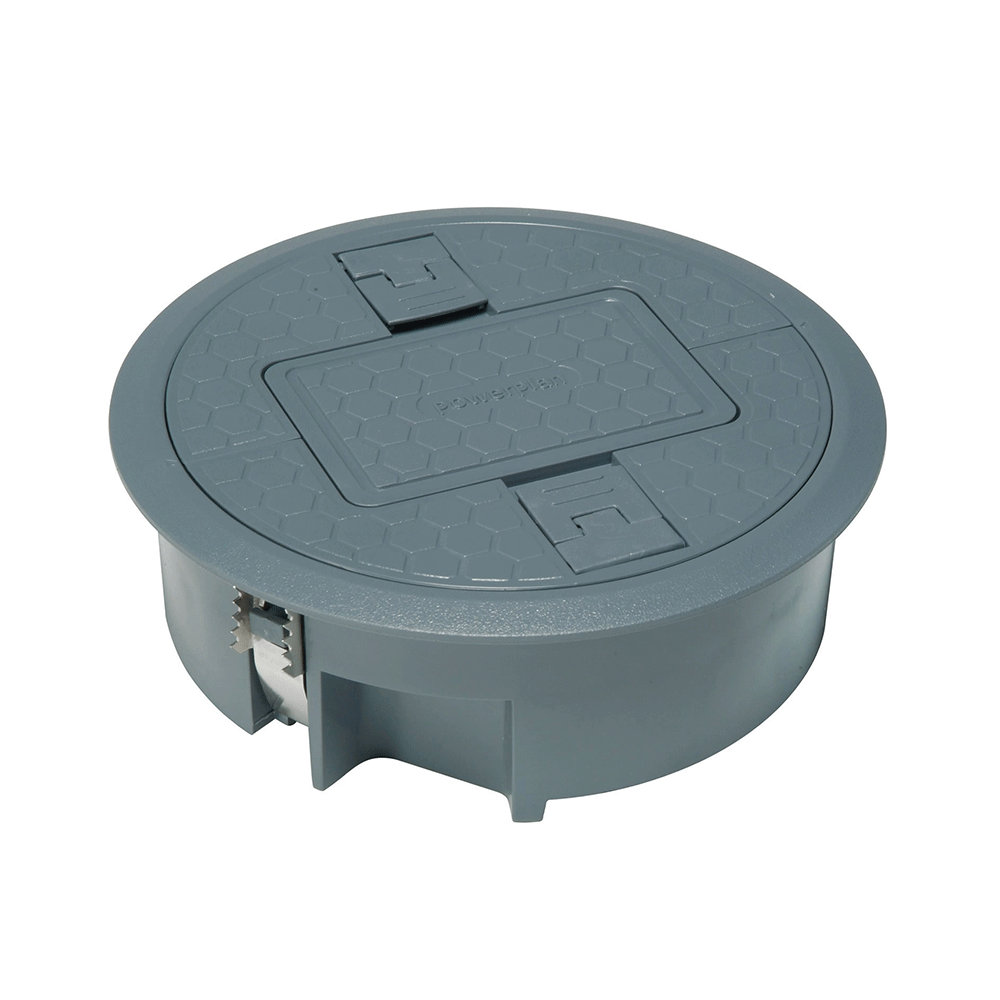

Floor grommets are circular ports installed to provide access to underfloor cables and sockets while keeping floors clear of wiring.

Suitable for most types of raised floors, their openings allow cables to travel from underfloor power systems to desks and workstations above. They have removable lids and are generally made of hard-wearing, flame-retardant plastics or polymers.